The Transformative Power of 3D Printing in Modern Manufacturing

Written on

In the expansive field of manufacturing, a revolutionary technology has surfaced, igniting waves of innovation and fundamentally altering industries. This technology, known as additive manufacturing or 3D printing, transforms concepts into reality, redefining the boundaries of production. Join us as we delve into the fascinating realm of this groundbreaking technology, examining its significant influence on diverse sectors, its capabilities, benefits, and the immense potential it offers for the future.

Enhancing Design and Prototyping

In design and prototyping, additive manufacturing stands out as a transformative force, sparking a creative revolution that transcends the limitations of conventional methods. With the ability to produce intricate and complex shapes, this technology empowers designers and engineers to expand the limits of creativity.

Historically, designers faced obstacles in converting their visionary ideas into tangible prototypes due to the constraints posed by subtractive manufacturing, like milling or cutting. Additive manufacturing eliminates these hurdles, opening up a realm of design possibilities.

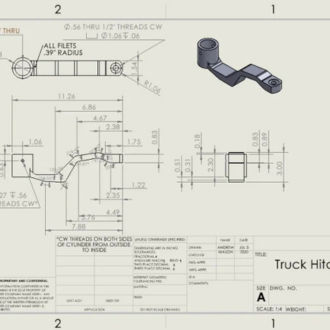

Visualize a designer sketching an innovative product digitally and, with a few clicks, materializing that design into a physical object. This technology facilitates the effortless transformation of digital designs into three-dimensional forms by constructing them layer by layer. This method enables the creation of detailed and complex prototypes that genuinely reflect the designers' visions.

The speed of prototyping with additive manufacturing is unmatched. Designers can quickly create functional prototypes, allowing for rapid iterations and refinements in their designs. This swift feedback loop shortens the product development timeline, leading to quicker market introductions and fostering innovation, granting companies a competitive edge in fast-paced sectors.

Moreover, additive manufacturing liberates designers from traditional manufacturing constraints. It easily accommodates the creation of complex shapes, internal channels, and intricate lattice structures. These capabilities herald new opportunities for innovation in fields such as aerospace, healthcare, and automotive. For instance, in aerospace, it allows for the creation of lightweight components with internal cooling passages, improving fuel efficiency and overall performance.

The design flexibility provided by additive manufacturing also supports the creation of bespoke and customized products. Traditionally, customization was often cost-prohibitive, limiting consumer options. However, this technology makes it feasible to produce unique items at scales and costs previously deemed impractical. From tailored consumer goods to personalized medical implants, additive manufacturing paves the way for distinctive and individualized experiences.

Furthermore, it encourages the exploration of new design approaches. Designers can experiment with new materials, shapes, and textures, crafting objects that were previously unattainable. This shift promotes a transition from mass production to mass customization, where products are uniquely tailored to individual preferences and needs.

Customization and Personalization

Additive manufacturing serves as a driving force for customization and personalization, fundamentally changing how products are imagined, developed, and enjoyed. The era of generic, mass-produced items that fail to resonate with individual tastes is over, giving way to a new age of tailored experiences.

Traditionally, manufacturing relied on economies of scale, producing large quantities of uniform products to satisfy demand. This standardization limited consumer choices. However, additive manufacturing challenges this model by offering unmatched customization opportunities.

Imagine a scenario where consumers can influence the design, features, and aesthetics of the products they buy. With additive manufacturing, this scenario becomes a reality. The technology allows for the incorporation of consumer preferences, enabling personalized versions of products to be crafted without extensive retooling or changes to production lines.

Customization in additive manufacturing goes beyond surface alterations; it allows products to be tailored to specific needs. For instance, in healthcare, this technology enables the creation of custom medical implants designed to fit individual anatomies, enhancing patient comfort and improving treatment outcomes.

Moreover, additive manufacturing opens doors to a new realm of personalized consumer goods. From custom jewelry to tailored fashion items, it empowers individuals to showcase their unique style and preferences. The ability to create one-of-a-kind pieces fosters a deeper emotional connection between consumers and products, enhancing satisfaction and brand loyalty.

This technology also facilitates on-demand and localized manufacturing, further amplifying customization possibilities. Instead of relying on centralized factories producing standardized items for a vast market, additive manufacturing allows for production closer to consumers, enabling rapid customization while minimizing transportation costs and delivery times.

In addition to catering to personal preferences, additive manufacturing supports the development of products that address specific market segments. Industries can utilize this technology to create specialized product variants for unique customer needs, enhancing market penetration and offering companies a chance to stand out in competitive landscapes.

Furthermore, additive manufacturing encourages a shift from product ownership to personalized service experiences. By integrating with digital platforms, companies can offer customized designs and virtual try-on options, allowing customers to co-create products and fostering a sense of ownership and pride.

Supply Chain Optimization

Additive manufacturing not only revolutionizes production processes but also transforms the entire supply chain landscape, introducing new levels of efficiency and responsiveness. Its decentralized and agile nature creates optimized supply chains capable of adapting to fluctuating market demands with remarkable speed and accuracy.

Conventional manufacturing often depends on centralized facilities, necessitating long-distance transportation of goods, which complicates logistics, extends lead times, and raises transportation costs. Conversely, additive manufacturing disrupts this model by enabling localized or on-demand production, redefining how products reach consumers.

Envision a future where products are manufactured closer to consumption points, eliminating extensive transport networks and reducing carbon footprints. Additive manufacturing can establish local manufacturing hubs, allowing goods to be produced near target markets. This decentralized approach enhances supply chain efficiency, ensuring quicker production and delivery times in response to customer demands.

Additionally, additive manufacturing introduces just-in-time production, minimizing inventory levels by creating products only as needed. Traditional manufacturing often requires maintaining large inventories to accommodate demand fluctuations and long lead times. However, additive manufacturing allows for on-demand production, reducing carrying costs and decreasing the risk of obsolescence, thereby improving cash flow.

The flexibility of additive manufacturing in supply chain management is unparalleled. It enables rapid adjustments to production processes to meet evolving customer needs. Manufacturers can quickly modify designs, iterate prototypes, and implement changes, ensuring they stay ahead in fast-changing markets where responsiveness is crucial.

Moreover, additive manufacturing supports distributed manufacturing networks. Instead of relying solely on large production facilities, companies can develop a network of smaller, localized sites. This reduces reliance on single-source suppliers, mitigates risks from disruptions, and enhances supply chain resilience. In cases of unforeseen events like natural disasters or geopolitical tensions, additive manufacturing allows for quick adaptations, ensuring continuity in production.

Additionally, it fosters collaboration and integration within supply chains. Digital design files and virtual communication platforms enable seamless sharing of designs, specifications, and production capabilities, promoting innovation and efficient supplier integration while enhancing overall supply chain performance.

“Lightweighting” and Material Efficiency

In manufacturing, the importance of weight and material efficiency is paramount in industries like aerospace, automotive, and robotics. Additive manufacturing emerges as a game-changer, reshaping the relationship between weight, strength, and material usage. By leveraging advanced design capabilities and optimized lattice structures, it facilitates the creation of lightweight components without compromising structural integrity.

Traditional manufacturing often necessitates large amounts of material to achieve the required strength and functionality, resulting in excess weight and higher energy costs. In contrast, additive manufacturing allows for precise material placement only where necessary, minimizing waste and enhancing efficiency.

Picture a scenario where a complex aerospace component is crafted with intricate internal lattice structures, significantly reducing its weight while retaining its mechanical integrity. Additive manufacturing empowers designers to optimize component geometry, leading to lightweight structures with improved load distribution. This approach translates into notable benefits, such as enhanced fuel efficiency in aerospace, improved energy efficiency in automotive applications, and greater agility in robotics.

Moreover, additive manufacturing offers unique design freedoms that unlock innovative lightweighting opportunities. Conventional manufacturing methods often impose restrictions on the complexity and shapes of components. However, additive manufacturing breaks these barriers, enabling the production of highly intricate and organic forms. This freedom facilitates the integration of lightweight structures, like lattices or hollow designs, that would be unfeasible using traditional techniques. The outcome is components with exceptional strength-to-weight ratios, surpassing previous expectations.

Additionally, it enables engineers to utilize advanced algorithms and optimization techniques for maximum material efficiency. With sophisticated computational tools, manufacturers can analyze and enhance the design and internal structure of components, achieving reduced weight while meeting necessary strength and performance standards. This optimization leads to significant material savings, lowering costs and minimizing environmental impact.

Furthermore, additive manufacturing broadens the spectrum of materials available for production. Traditional techniques often limit material choices due to processing constraints. However, additive manufacturing accommodates a wide variety of materials, including advanced alloys, composites, and even bio-based polymers. These materials provide unique characteristics such as high strength-to-weight ratios and improved thermal resistance, enhancing component performance while reducing weight.

The benefits of lightweighting and material efficiency extend beyond individual components, leading to substantial energy savings and environmental advantages. In the transportation sector, for instance, lightweighting achieved through additive manufacturing can contribute to lower fuel consumption, reduced greenhouse gas emissions, and increased sustainability.

Supply Chain Resilience and On-Demand Manufacturing

The conventional global supply chain often faces vulnerabilities due to unforeseen events like natural disasters, geopolitical tensions, or pandemics. Additive manufacturing stands out as a transformative solution, providing exceptional resilience and the capability to implement on-demand manufacturing strategies.

Consider a situation where a natural disaster impacts a crucial manufacturing area, hindering the production and distribution of essential components. In such cases, additive manufacturing presents a viable alternative. By decentralizing production and enabling local manufacturing, it reduces reliance on centralized hubs, lowering the risk of supply chain disruptions. Companies can create distributed manufacturing networks, allowing for rapid adjustments to production locations and ensuring a steady supply of products.

Additive manufacturing also facilitates on-demand production. Traditional manufacturing, with its long lead times and large production runs, often leads to excess inventory or stock shortages. Conversely, additive manufacturing eliminates the need for extensive inventory storage, as products can be created as required. This on-demand approach optimizes inventory levels, reduces holding costs, and mitigates the risk of obsolescence, enhancing supply chain efficiency.

Additionally, additive manufacturing allows for the establishment of virtual inventories. Instead of maintaining physical stock of a wide range of products, companies can store digital design files, producing items based on customer orders. This digital inventory strategy minimizes the need for large warehouses, cutting down on holding costs while offering greater flexibility to adapt to changing market demands. Moreover, virtual inventories enhance customization capabilities, enabling personalized product variations without significant physical storage needs.

Additive manufacturing also promotes agile manufacturing, allowing for rapid design changes, prototyping, and production adjustments. Manufacturers can swiftly respond to evolving customer needs, market trends, or unexpected disruptions. This agility fosters a dynamic and resilient supply chain ecosystem, where companies can pivot their production strategies as circumstances change. Whether modifying designs, altering production parameters, or shifting focus to new product lines, additive manufacturing empowers businesses to remain flexible and responsive.

Furthermore, it supports sustainable supply chains. Traditional manufacturing processes often waste raw materials due to inefficiencies. Additive manufacturing minimizes waste by using only the necessary material for each component, contributing to environmental sustainability and resource conservation. Additionally, localized production through additive manufacturing lowers carbon footprints associated with long-distance transportation, further enhancing supply chain sustainability.

Sustainability and Environmental Benefits

As the global community faces increasing environmental challenges, additive manufacturing emerges as a transformative force in promoting sustainability and reducing the ecological impact of production processes. By revolutionizing material use, minimizing waste, and enabling localized production, it presents a pathway to greener, more eco-friendly industries.

Traditional manufacturing often generates significant material waste through subtractive techniques or the constraints of molding and casting. In contrast, additive manufacturing minimizes waste by employing only the necessary material to construct components layer by layer. This precise material usage dramatically reduces waste, conserves resources, and lowers the overall environmental impact of manufacturing.

Imagine a future where complex components are created with minimal waste, eliminating the need for costly machining processes. Additive manufacturing's capability to produce intricate designs and optimized internal structures significantly contributes to material savings. This reduction in material use results in less resource extraction, lower energy consumption, and diminished carbon emissions linked to material processing.

Additionally, additive manufacturing encourages the use of sustainable materials and alternative feedstocks. It accommodates a diverse array of materials, including bio-based polymers, recycled plastics, and those derived from renewable sources. By utilizing these sustainable materials, additive manufacturing diminishes reliance on traditional petroleum-based products, endorsing circular economy principles and supporting the development of a more sustainable supply chain.

Moreover, it plays a critical role in reducing energy consumption throughout manufacturing processes. Traditional methods often involve energy-intensive tasks such as machining or forging, while additive manufacturing consumes less energy, primarily during the melting or curing phases. This energy efficiency leads to reduced greenhouse gas emissions and aids in mitigating climate change.

Furthermore, additive manufacturing promotes localized and on-demand production, which minimizes transportation needs and their associated carbon emissions. In conventional manufacturing, goods are often produced in one location and shipped over long distances. This transport-heavy model contributes to pollution and increased emissions. However, additive manufacturing enables localized production, bringing manufacturing closer to consumers and thereby reducing transportation-related carbon footprints, leading to a more sustainable supply chain.

Additionally, it allows for the design and creation of products with optimized shapes and functionalities, enhancing energy efficiency during their use. For example, in the automotive sector, additive manufacturing enables the production of lightweight components that aid in fuel savings and lower emissions. Similarly, in aerospace, it facilitates the creation of aerodynamic and lightweight structures, improving fuel efficiency and lessening the environmental impact of aviation.

“The future of manufacturing is being shaped by the revolutionary capabilities of additive manufacturing, and its potential to reshape industries and create a more sustainable and efficient world is truly remarkable. Embracing this transformative technology is not just a choice but a necessity for businesses to thrive in a rapidly evolving global marketplace. The era of additive manufacturing has arrived, and its impact on manufacturing processes will continue to shape the industries of tomorrow.”